- EQUIPMENT

- ATTACHMENTS

- POWER SYSTEMS

- TECHNOLOGY

- AGRICULTURE

October 4, 2022

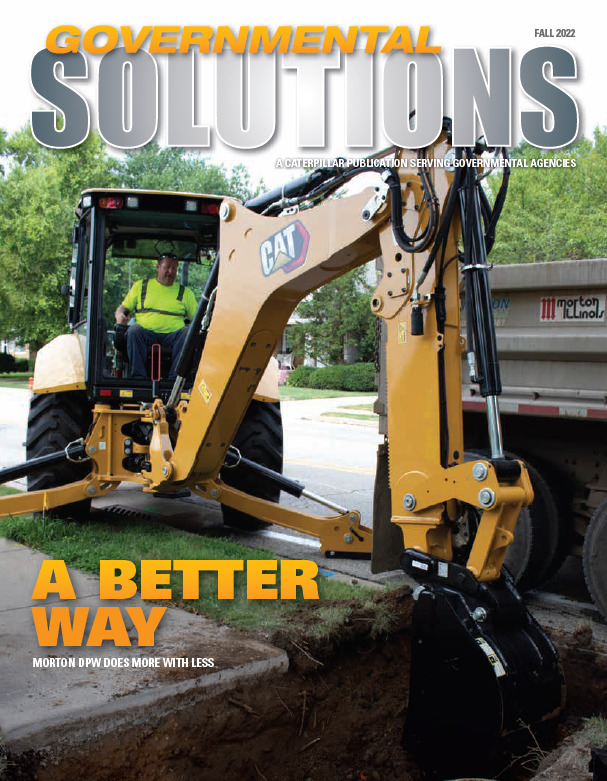

While many public works departments struggle to handle a wide variety of tasks with limited equipment fleets, the Village of Morton, Ill., pop. 17,000, has no such concerns.

As Director of Public Works, Craig Loudermilk’s approach is doing more with less. Though relatively small, Morton’s DPW fleet, is well equipped to handle most any assignment. With wide-ranging departmental responsibilities that include water distribution, water treatment, wastewater, stormwater, gas, streets, and pretty much everything else involving public works, Loudermilk mixes and matches machines and attachments to maximize productivity across the board.

“We’ve been trying to come together more because sharing enables us to acquire more equipment—Cat® machines like excavators, wheel loaders and backhoe loaders. We do share and try to coordinate as best we can to maximize equipment usage and operate more efficiently.”

With retirements and a shrinking labor pool, Loudermilk understands that as he hires younger staff, he must pursue greater efficiencies. Plus he’s always asking his team members: “What can we do better?”

This prescient approach has resulted in Morton’s small team of 35 workers becoming highly efficient with their Cat fleet, which is comprised of three Backhoe Loaders, a 926 Wheel Loader, 289D3 XPS Compact Track Loader and a 306 Mini Excavator. Most of the machines log about 500 hours annually. Morton’s fleet of Cat equipment is complemented by 25 Cat attachments that add extraordinary versatility, giving the fleet far greater capabilities to perform any job, work assignment or emergency repair that could possibly arise.

“We purchase the equipment, but it’s the attachments that our Cat dealer provides that really make all of this work,” Loudermilk says.

Prior to the start of each new year, Loudermilk takes inventory of Morton’s equipment fleet and work tools to determine what else they might need and what his DPW budget can afford, then he adds things accordingly.

“If you talk to my street crew, the cold planer attachment for the small compact track loader was a game changer for us,” he says. “We do a lot of patching work, filling potholes and related work. Historically, we would grab the backhoe, sock up the patch and we’d dig it up full depth. But now the guys are so happy because using the cold planer we’re only removing an inch and a half and filling that in. It’s a lot better to compact against existing pavement, and we’re doing more twice the amount of patching work now, which is a big part of what we do here.”

In addition to the cold planer, some of the many other work tools include a utility broom, hammers, compactor, forks, and assorted buckets, including a multi-purpose design.

Besides achieving greater efficiencies, Loudermilk adds that Morton’s super-efficient fleet utilization completes so much more work that it has essentially enabled them to double the overall volume of work compared to the past. Jobs performed by the village’s DPW crew include: Installing water mains, repairing water leaks and hydrants, replacing failing pipes, placing manholes, performing sewer and drain repairs, doing street repair and patching, laying down new asphalt and concrete, and general utility work.

Plus, crews excavate trenches for water distribution and a great deal of general service work, running service lines up to commercial and residential dwellings. Additionally, the village’s significant need for aggregate means Morton maintains a large maintenance yard, stockpiling material and loading trucks year-round.

Morton acquires its machines by purchasing through Sourcewell, a national cooperative purchasing organization that holds hundreds of competitively solicited cooperative contracts ready for use. Sourcewell helps governments, educational agencies, and nonprofits work more efficiently by offering a wide range of cooperative contracts. This enables agencies to save time and money by combining

the buying power of more than 50,000 governmental, educational, and nonprofit organizations.

“Purchasing through Sourcewell saves a tremendous amount of time in the buying process,” Loudermilk says. “It ensures we secure the best possible price, and results in faster machine deliveries.”

The only exception is the Cat 926 Wheel Loader, which is leased for five-year increments to help protect against the brutal wear conditions and salt damage incurred during Illinois winters.

The village acquires its machines in five-year guaranteed buybacks, which enables Loudermilk to update the DPW fleet on a planned basis in sync with annual budgets.

When special project needs arise, such as a stump removal, Loudermilk relies on the Altorfer Rental Store

for any special attachments that may be needed on a short-term basis.

Morton’s DPW operators appreciate the roadability of the rubber-tired backhoe loaders, wheel loader and compact track loader that enable them to move quickly and easily between jobsites.

Loudermilk says the stick steer on the new Next Gen 306 Mini Excavator is very popular with operators

because it helps them trace their production and move the machine around to places they typically couldn’t get to as quickly with previous models.

Cruise control is another popular feature on the mini excavator, as it enables continuous travel without holding the levers or joystick down, with the ability to safely stop the machine in several ways. It’s great for tracking or grading long distances since you just need to steer.

Morton’s full-time service technician handles all machine maintenance needs and appreciates the fact that all of Morton’s Cat machines are equipped with activated Product Link™ to help monitor the condition of the machines, including hours logged since regular maintenance was last performed.

Further testament to the confidence that the Village of Morton has in Cat equipment is the fact that Morton facilities operate 12 Cat backup generators that serve their water treatment and wastewater treatment plants, police department, public works garage and facilities center. All generators are diesel powered except one, a natural gas-powered unit provides standby power for the fire department.

The Village of Morton enjoys an excellent working relationship with Altorfer sales rep, Regan Jones, and the entire Altorfer team. “I like working with Regan because he understands what we do,” Loudermilk says. “He’s been in the business and knows what we do, so that makes for a solid working relationship with him.

“He obviously has access to all my guys and communicates well—that’s an expectation of mine—to talk to my mechanic and my operators. That way they can call him directly if they have any questions or concerns. And the relationship we have is great—it makes my life a lot easier with the quality of the equipment backed by highly responsive service. The bottom line is, it saves a lot of time and money for the village.”